Spiralock® Thread Turning Carbide Inserts

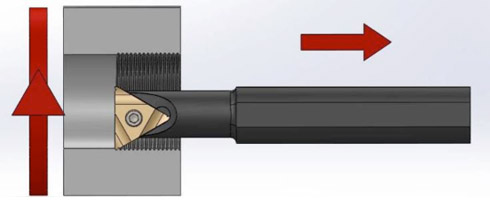

Thread turning is another option for making internal threads when tapping conditions are not optimal, such as parts with large diameters or in difficult-to-cut materials. Thread turning is most often performed on a lathe with a cylindrical workpiece and uses an indexable carbide insert with a boring bar. When boring bars are too large for the size of hole, a solid carbide threading bar can be used. In thread turning, the workpiece rotates as the cutting tool moves axially to create a continuous thread path. Like thread-milling, it normally takes multiple passes to generate a full thread profile. Unlike a thread-milling cutter, all the material removal is accomplished with only one cutting edge engaged. Removing only a fraction of the thread depth in each pass keeps the cutting edge from being overloaded.

Insert Selection Process:

- Determine thread size and minimum minor diameter

- Determine minimum bore size smaller than the minor diameter from the chart below

- Select appropriate insert blank size for minimum bore

- Select Spiralock® part number for corresponding insert blank and pitch size using chart below

| Min. Bore | Insert Size | Pitch Range | Boring Bar (example) |

|---|---|---|---|

| 0.240 | 06 | 20-32 TPI (1.00-0.45 mm) | SIR 0205 H06 |

| 0.310 | 08 | 16-32 TPI (1.50-0.45 mm) | SIR 0265 K08 |

| 0.350 | 08 | SIR 0310 K08 | |

| 0.470 | 11 | 14-32 TPI (1.75-0.45 mm) | SIR 0375 H11 |

| 0.470 | 11 | SIR 0375 K11 | |

| 0.470 | 11 | SIR 0375 M11 C | |

| 0.580 | 11 | SIR 0500 L11 | |

| 0.580 | 11 | SIR 0500 P11 C | |

| 0.640 | 16 | 7-32 TPI (3.50-0.45 mm) | SIR 0500 M16 |

| 0.750 | 16 | SIR 0625 P16 | |

| 0.750 | 16 | SIR 0625 R16 C | |

| 0.900 | 16 | SIR 0750 P16 | |

| 1.160 | 16 | SIR 1000 R16 | |

| 1.400 | 16 | SIR 1250 S16 | |

| 1.650 | 16 | SIR 1500 T16 | |

| 0.900 | 22 | 6 TPI (5.00-0.45 mm) | SIR 0750 P22 |

| 1.160 | 22 | SIR 1000 R22 | |

| 1.500 | 22 | SIR 1250 S22 |

| Ordering Code: | SPL part number | + Modifiers |

|---|---|---|

| No suffix for Right Hand threads or BT thread direction Add ‘LH’ for Left Hand threads Add ‘TT’ when cutting from opposite end of a through hole |

Example: SPL90154LH is an 18-pitch insert for cutting left-hand Spiralock® threads, and is made from an ISO size 16 blank

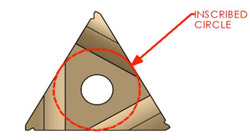

| Part Number | Pitch | ISO Blank Size / Inscribed Circle |

|---|---|---|

| SPL90324 | 32 | 06 (5/32”) |

| SPL90326 | 28 | |

| SPL90328 | 24 | |

| SPL90330 | 20 | |

| SPL90332 | 18 | |

| SPL90334 | 32 | 08 (3/16”) |

| SPL90336 | 28 | |

| SPL90338 | 24 | |

| SPL90340 | 20 | |

| SPL90342 | 18 | |

| SPL90344 | 16 | |

| SPL90114 | 32 | 11 (1/4”) |

| SPL90116 | 28 | |

| SPL90118 | 27 | |

| SPL90120 | 24 | |

| SPL90122 | 20 | |

| SPL90124 | 18 | |

| SPL90126 | 16 | |

| SPL90128 | 14 | |

| SPL90144 | 32 | 16 (3/8”) |

| SPL90146 | 28 | |

| SPL90148 | 27 | |

| SPL90150 | 24 | |

| SPL90152 | 20 | |

| SPL90154 | 18 | |

| SPL90156 | 16 | |

| SPL90158 | 14 | |

| SPL90160 | 13 | |

| SPL90162 | 12 | |

| SPL90164 | 11.5 | |

| SPL90166 | 11 | |

| SPL90168 | 10 | |

| SPL90170 | 9 | |

| SPL90172 | 8 | |

| SPL90174 | 7 | 22 (1/2”) |

| SPL90176 | 6 | |

| SPL90300 | 0.50 | 06 (5/32”) |

| SPL90302 | 0.75 | |

| SPL90304 | 1.00 | |

| SPL90308 | 0.50 | 08 (3/16”) |

| SPL90310 | 0.75 | |

| SPL90312 | 1.00 | |

| SPL90314 | 1.25 | |

| SPL90316 | 1.50 | |

| SPL90014 | 0.80 | 11 (1/4”) |

| SPL90016 | 1.00 | |

| SPL90018 | 1.25 | |

| SPL90020 | 1.50 | |

| SPL90022 | 1.75 | |

| SPL90038 | 0.80 | 16 (3/8”) |

| SPL90040 | 1.00 | |

| SPL90042 | 1.25 | |

| SPL90044 | 1.50 | |

| SPL90046 | 1.75 | |

| SPL90048 | 2.00 | |

| SPL90050 | 2.50 | |

| SPL90052 | 3.00 | |

| SPL90054 | 3.50 | 22 (1/2”) |

| SPL90056 | 4.00 | |

| SPL90058 | 4.50 | |

| SPL90060 | 5.00 | |

| SPL90062 | 5.50 | 27 (5/8”) |

| SPL90064 | 6.00 |